EAMC original creation, dozens of domestic and foreign invention patents, independent intellectual property rights

EAMC original creation, dozens of domestic and foreign invention patents, independent intellectual property rights

Multipurpose in one machine

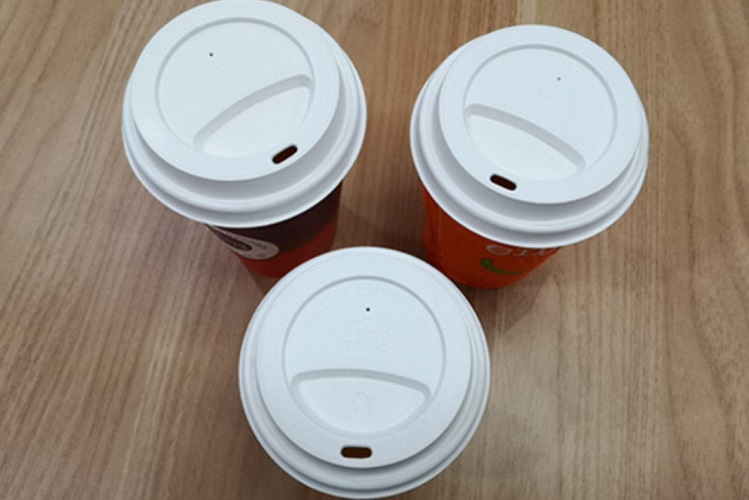

The same equipment is suitable for the production of "environmental-friendly tableware", "Hot drink cup lid with inverted buckle", "premium small-angle industrial packaging", "boutique egg box, egg tray, fruit and vegetable tray", etc.

High productivity, high automation, low energy consumption, low labor cost

The direct production cost of the product is greatly reduced, which is about 30% lower than the conventional equipment.

It integrates fully automatic forming, shaping, trimming and punching all in one, with simple and sophisticated design, compact structure, and small footprint

The production capacity of the same area of the production workshop is the capacity of 2~3 workshops of similar machines. Greatly reduce civil construction costs, plant rents, and management costs

Fully enclosed safety protection

European and American design standards, the machine will automatically stop when the door is opened during operation

EAMC's patented technology. With more than 30 years of experience in the development and application of fully automatic pulp mold environmentally friendly tableware production line. The EAMC fully automatic pulp molding production line completely overcomes the common problems of conventional pulp molding equipment.

EAMC full automatic cake tray pulp molding machine is an equipment which produces biodegradable environmental protection cake trays

The fully automatic production line of "paper cup lid - molded pulp (fiber) cup lid cup lid with inverted buckle" developed by EAMC is more advanced and competitive. No need for secondary processing, one-time forming "cold and hot drink cup lid with inverted buckle".