The fully automatic production line of "paper cup lid - molded pulp (fiber) cup lid with inverted buckle" developed by EAMC is more advanced and competitive. No need secondary processing, one-time forming "cold and hot drink cup lid with inverted buckle".

Traditional plastic cup lids do not degrade and can cause white pollution to the environment. So molded fiber (pulp) cup lids are needed to replace the plastic cup lids.

EAMC has applied for a patent of molded fiber (pulp) cup lids with inverted buckle: "A moulded fiber cup lid with an inner convex ring", and has obtained a patent certificate,Patent No. ZL201921831120.0.

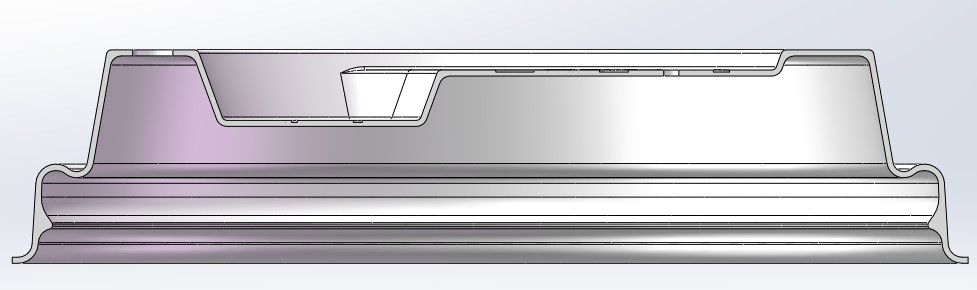

"A moulded fiber cup lid with an inner convex ring", is described as follows: The inner convex ring of the cup lid is actually a "buckle", Its role and effect: Put the cup lid "stuck" on the "ring mouth edge" of the cup, play the "reverse buckle" role. This "inverted buckle" is the inner convex ring of the cup lid, The inner convex ring of the cup lid has two functions: 1. Let the cup lid be in close contact with the "ring mouth edge" of the paper cup; 2, the cup lid does not easily fall off the cup when the cup is dumped.

The inner convex ring of the cup lid is directly squeezed inward by the wet blank of the cup lid during the hot pressure forming process. Keep the outside of the cup lid smooth and set an inner convex ring on the inside of the cup lid, Such a cup lid structure, beautiful, sealing effect, prevent shedding; convenient production forming, significantly reduce the production cost.